Automotive

Due to the intelligent development of automobiles, the application range of SMT equipment in the automotive field is becoming more and more extensive.

Aerospace

Modern aerospace systems are set to rely even more heavily on electronic systems in the future, given the increased use of high standard electronic devices.

Electronics

The PCB world is rapidly innovating to keep up with consumer demand. The growing interest in devices that are smaller but process information faster is driving new approaches.

Medical

In terms of medical PCB requirements, the medical industry demands the highest standards of quality, precision and reliability, flexibility and safety.

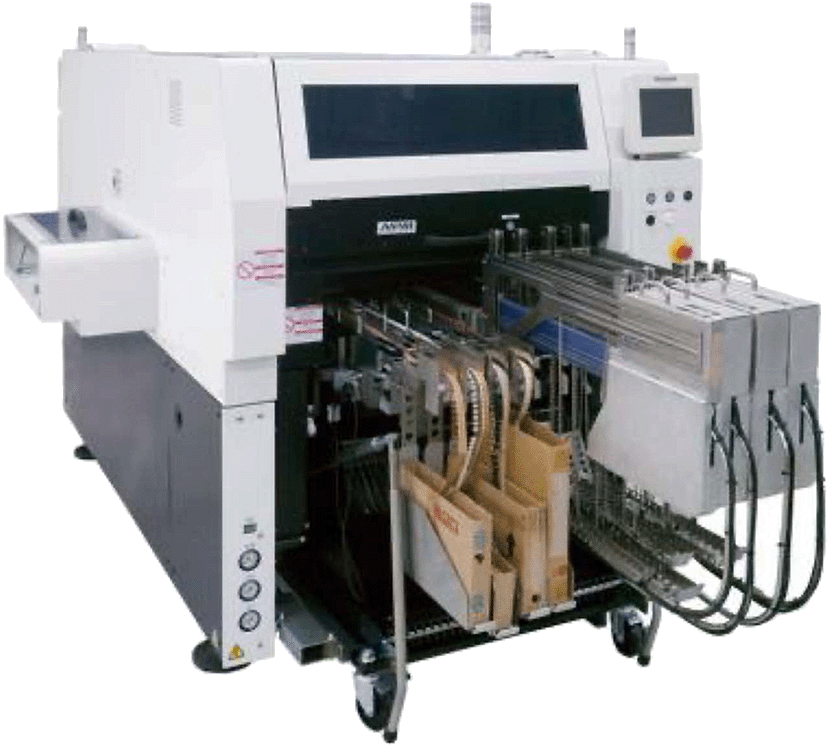

Mounting (SMT)

Best-in-class placement solutions from entry level to more complex requirements for any mix, any volume, any time smart manufacturing. High placement quality and high throughput are the characteristics of Panasonic’s placement machines, the next generation of smart pick and place equipment. In combination with the Panasonic software environment and embedded into an Industry 4.0 philosophy, the user can expect a modern shop floor management system including various remote operation options, feeder setup navigation, component supply navigation etc.

Mounting

Product Range

Best-in-class placement solutions from entry level to more complex requirements for any mix, any volume, any time smart manufacturing.

Microelectronics Solutions

Delivering the latest systems for: plasma dicing and dry etching of wafers; plasma cleaning of wafers and substrates; and high quality ultrasonic flip-chip bonding of bare ICs. We provide a line-up of cutting-edge microelectronics equipment to help our customers reduce production costs and increase quality. By using an argon plasma treatment, ultra-thin gold-plated electrodes can be wire-bonded reliably without the formation of nickel compounds. The savings achieved in cheaper gold plating can provide the ROI justification alone.

Microelectronics

Product Range

Delivering the latest systems for: plasma dicing and dry etching of wafers; plasma cleaning of wafers and substrates; and high quality ultrasonic flip-chip bonding of bare ICs.

Insertion (THT/PTH)

Panasonic's insertion platforms for radial and axial processes with high density and high speed. PTH / THT (Pin Through Hole / Through Hole Technology) solutions. The efficient pick and place machine contributes to reduce manpower requirements and to consistent production with high productivity, flexibility and high-quality pick and place results. The flexible machines are ideal machines for cycle-optimized production, especially for companies that must process both types of components due to the increased demand from power electronics for THT assemblies.

Printing (SMT)

High-quality, reliable screen-printing technology for producing any assembly. Together with Panasonic’s software solutions, the machines are a trendsetting screen printers for Industry 4.0 applications. Various features minimize the line management. The printing performance of the SPG2 can be carried out in 14s with a process repeatability of ± 15μm. Larger circuit boards up to 510mm x 510mm can be handled without restrictions. A new programmable squeegee angle increases the filling pressure by up to 10%.

Customer Support

Need Help? Chat with us on Whatsapp