Automotive

Due to the intelligent development of automobiles, the application range of SMT equipment in the automotive field is becoming more and more extensive.

Aerospace

Modern aerospace systems are set to rely even more heavily on electronic systems in the future, given the increased use of high standard electronic devices.

Electronics

The PCB world is rapidly innovating to keep up with consumer demand. The growing interest in devices that are smaller but process information faster is driving new approaches.

Medical

In terms of medical PCB requirements, the medical industry demands the highest standards of quality, precision and reliability, flexibility and safety.

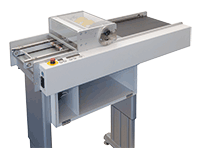

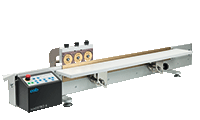

PCB Separators

MAESTRO PCB separators are in use in many modern electronics facilities. At these, separating assembled PCB from multiple panels is a standard discipline. CAB provides helpful solutions. MAESTRO 2 and 3E models require little footprint. On a MAESTRO 4S, milled grooves on PCB made of FR4 or aluminum are traversed several times by the circular blade. Components assembled along the groove are subject to minimum stress. Defects are avoided. Operators benefit from separations of perfect quality. A maximum of 15 PCB arranged in multiple panels can be separated simultaneously by MAESTRO 5L. Separated PCB are conveyed by an integral belt. MAESTRO 6 models provide three blades next to one another for single-traverse separation. Units are offered in various construction widths, separating even extra-long materials up to 1,500 mm.

PCB Separators

Product Range

Separate PCBs with pre-scored groove – precise, fast and economical. Separation means significant mechanical stress. Resistors, microcontrollers and condensers, assembled close to the milled groove on little space, might be damaged. CAB MAESTRO devices have been developed for low-stress PCB separation.

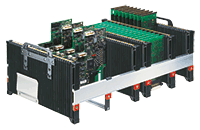

PCB Magazines

The latest assembly plants are adapted individually several times a day. To transport PCB of different sizes, magazines must adjust consecutively to widths. Depending on the magazine, widths are set using screws or a toothed belt, the latter been adjusted by hand or by a motor. CAB series 800 magazines provide a coupling. When inserting a magazine onto a loader in an assembly plant, the flange on the servo motor of the loader connects to the coupling. The flexible side wall of the magazine moves on threaded spindles with uniform precision to a reference spot. Parallelism is provided. Then the magazine automatically adjusts to the width of the assembled PCB as specified by the plant control. There is no need for providing magazines pre-adjusted on stock.

PCB Magazines

Product Range

Precision, stability and flexible handling are important features for the use of the PCB magazines in automated assembly lines. To transport PCB of different sizes, magazines must be adjusted consecutively.

Customer Support

Need Help? Chat with us on Whatsapp