Automotive

Due to the intelligent development of automobiles, the application range of SMT equipment in the automotive field is becoming more and more extensive.

Aerospace

Modern aerospace systems are set to rely even more heavily on electronic systems in the future, given the increased use of high standard electronic devices.

Electronics

The PCB world is rapidly innovating to keep up with consumer demand. The growing interest in devices that are smaller but process information faster is driving new approaches.

Medical

In terms of medical PCB requirements, the medical industry demands the highest standards of quality, precision and reliability, flexibility and safety.

NEW 3Di Series

Saki's new 3D AOI series delivers greater flexibility with the option to upgrade the camera system and customize the optical resolution and lighting according to specific production needs or the manufacturing environment. To handle today’s rapidly changing market trends, the system can handle complex inspection challenges such as high component mounting density areas containing highly miniaturized parts placed near much larger and taller component. With our new 3D AOI system, you can strengthen quality assurance and increase production efficiency.

3D AOI

Product Range

Saki’s 3D Automated Optical Inspection Systems Series applies cutting edge technologies to improve production efficiency and enhance production quality across the entire assembly line.

Inline 3D-CT AXI Systems

Saki's 3D-AXI (X-Ray) series adds significant inspection capability. The system utilizes Planar Computed Tomography (PCT) providing high precision CT imaging at high speed. "Planar CT" technology enables inspection without any interference from the opposite side of the board making possible for the system to display 3D reconstruction, 3D inspection, and 3D image for all captured images of PCBs as well as semiconductors and power modules.

3D SPI Systems

Saki's 3D SPI identifies critical defects and assists with process improvement. Select from a variety of options including machine size, inspection resolution, hardware and software features to meet your specific requirements. Machines are designed with unique gantry systems, technologies, and inspection algorithms to deliver highly accurate, high speed, and user friendly measurement systems. Automatic Self-diagnostic functionality monitors machine performance.

3D SPI

Product Range

Saki's 3D Solder Paste Inspection Machine identifies critical defects and assists with process improvement. Saki SPI identifies critical defects increasing yield and eliminating re re-work.

2D AOI Systems

Saki’s unique line scanning technology and coaxial overhead lighting enables high-speed accurate inspection. The line scan technology is a main feature of Saki Corporation that is able to detect FOD and extra components across the entire surface of the PCB. Using this technology, a whole PCB can be scanned in high-speed. The unique telecentric lens optical system and the coaxial overhead lighting eliminate shadowing, improve capability and reduces production start-up time.

2D AOI

Product Range

Saki’s unique and proprietary Line Scanning System inspects an entire PCB 'on-the-fly' in just one pass. The system projects multiple lights at different angles onto the substrate obtaining high resolution images in one scanning operation.

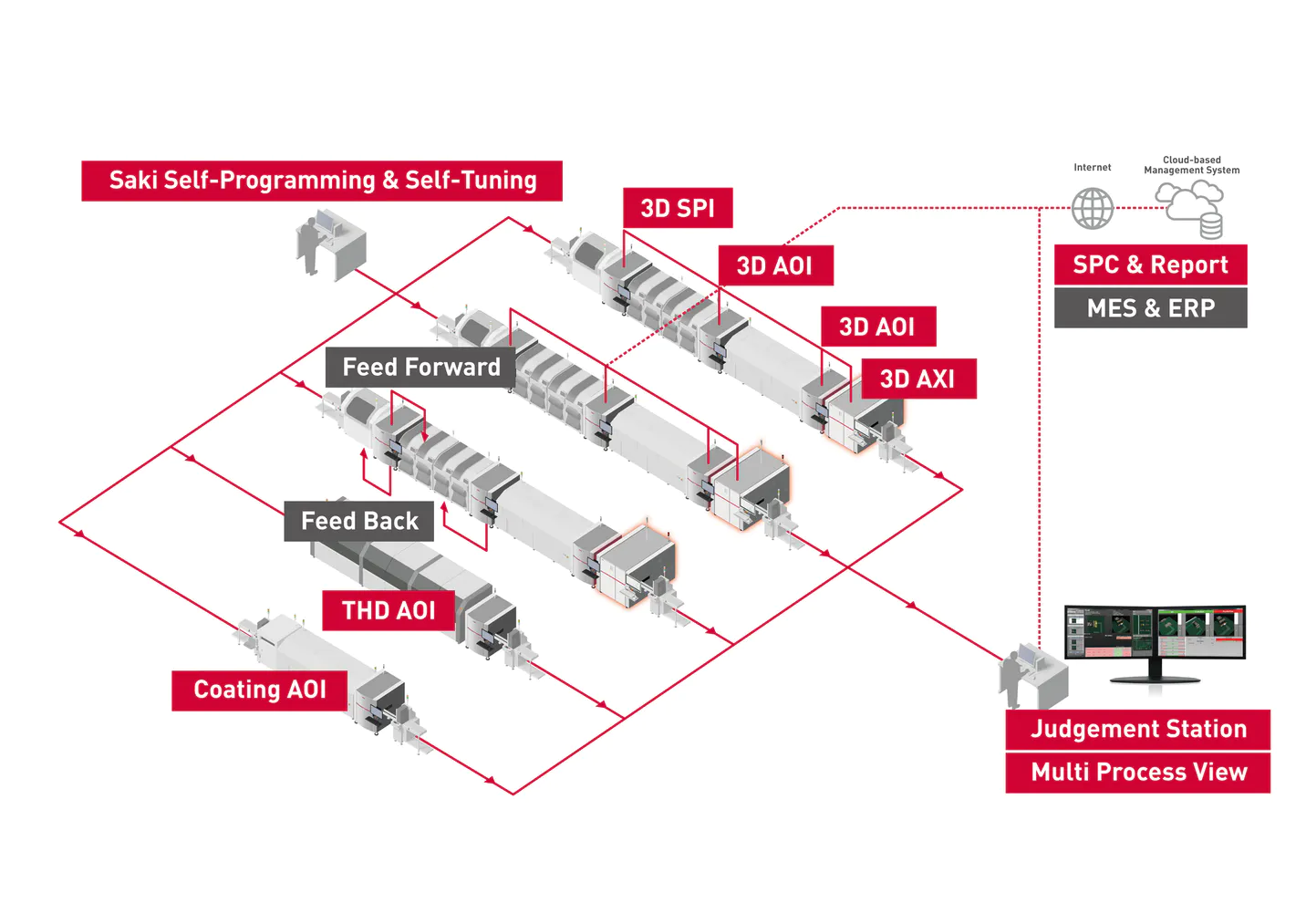

Software

Solutions for efficiency and quality improvement in multi-line facilities. Saki's high-speed, high-accuracy inspection and measurement systems, with enhanced software and hardware platforms, satisfy the market demand of advanced manufacturing, high-mix low-volume production, precision quality, short lead times, and low total cost-of-ownership. Saki's data capture capabilities and machine-to-machine (M2M) connectivity maximize production efficiency for the Smart Factory and offer a data-driven approach to continuous productivity improvement by collecting and statistically analyzing the operating status and inspection results of all equipment in the production line.

Software Range

Saki's Support Systems. Solutions for efficiency and quality improvement in multi-line facilities.

Customer Support

Need Help? Chat with us on Whatsapp