Automotive

Due to the intelligent development of automobiles, the application range of SMT equipment in the automotive field is becoming more and more extensive.

Aerospace

Modern aerospace systems are set to rely even more heavily on electronic systems in the future, given the increased use of high standard electronic devices.

Electronics

The PCB world is rapidly innovating to keep up with consumer demand. The growing interest in devices that are smaller but process information faster is driving new approaches.

Medical

In terms of medical PCB requirements, the medical industry demands the highest standards of quality, precision and reliability, flexibility and safety.

Automated Programming Systems

Engineered for speed and accuracy, the automated systems give you blazing fast throughput, the highest uptime, unprecedented capability & quality, flexibility, and fast changeover for the lowest total cost of ownership. The systems are designed for easy set-up & reliable performance using the integrated systems software and handling technology for highest quality yield. Ultra-fast programming delivering revolutionary performance, managed and secure programming at a revolutionary value.

Automated Programming Product Range

Data I/O offers a variety of manual and automated programming systems to support customers moving from NPI and First Article into volume production seamlessly. Data I/O’s manual programmers use the same programming core as our automated systems supporting a dispersed supply chain with production in one geography and production in another.

Manual Programmers

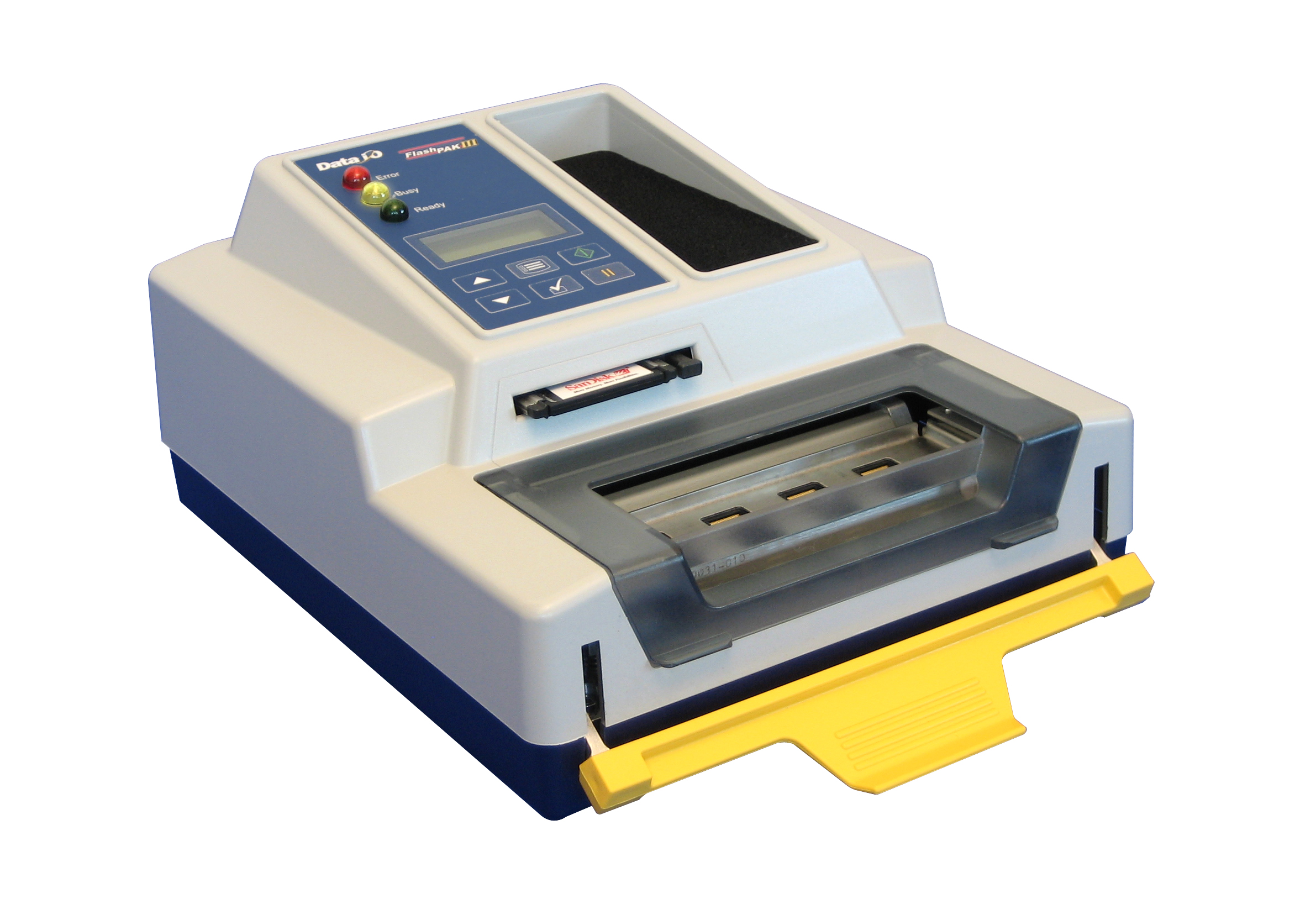

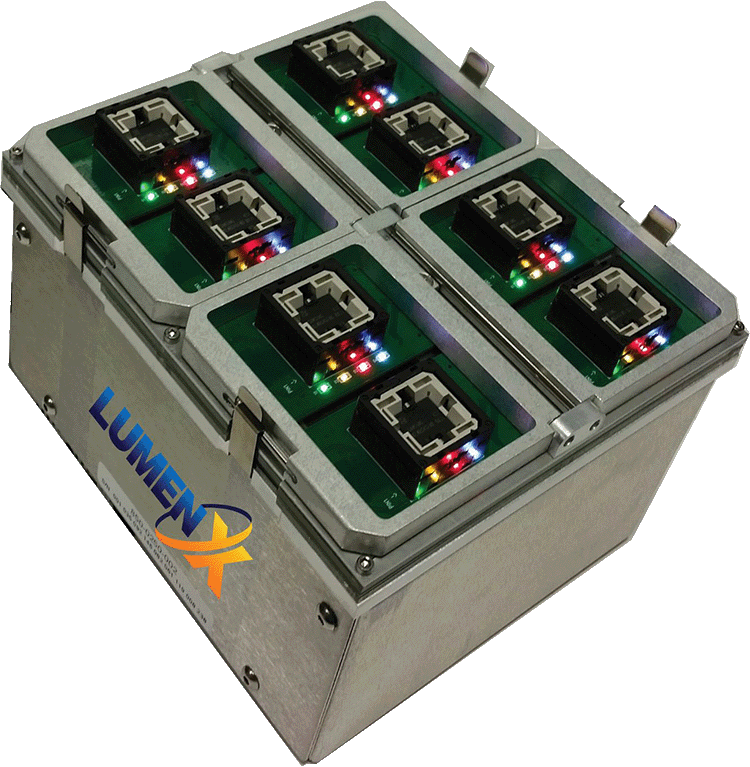

Highest Quality Manual Programming. The FlashPAK III is the world’s most trusted manual desktop gang programmer. The FlashPAK III is meticulously designed with the same attention to detail, quality, and reliability that Data I/O’s automated programming systems are known for. The LumenX Desktop is a revolutionary programming platform with unrivaled performance at an extraordinary value, engineered to maximize manufacturing velocity with rapid download, program, and verify speeds while being able to manage and secure your programming job from design through manufacturing for the highest quality.

Manual Programmers

Product Range

We are committed to delivering the highest quality programming solutions and driving continuous improvements in all manufacturing locations. Data I/O's Quality Management System (QMS) governs the processes for product design, development, and manufacture.

Software

Programmable devices continue to play an increasingly important role in mission-critical devices. ABS braking systems, engine control units, glucose monitors, defibrillators, pacemakers, building control systems and more rely on devices to be correctly programmed and free from handling defects to operate properly. Global automotive, medical, and industrial controls electronics manufacturers trust Data I/O to meet their demanding quality requirements. With the Automotive Performance PAK, you can customize your Data I/O’s automated handlers to meet your specific requirements.

Customer Support

Need Help? Chat with us on Whatsapp